Why should we always hold onto example pieces when making lingerie? It’s really important for your orders.

Keeping reference samples in lingerie manufacturing matters because it ensures consistent product quality across orders, prevents disputes with transparent comparisons, supports buyer traceability, standardizes reorders, and builds trust for strong, long-term partnerships in your supply chain.

I know that for you, as a B2B buyer for wholesalers, distributors, or your own brand, consistency is key. When you order a batch of daily fashion bra sets or period panties, you expect them to be exactly like the one you approved. At XIESHENG, with our monthly capacity of 400,000 bras and 400,000 panties, we produce a huge volume. Ensuring every single item meets your standard is a big job. This is where keeping reference samples becomes incredibly important. They are not just small pieces of fabric or finished items; they are the physical benchmarks that guarantee the quality and specifications of your intimate apparel orders. We understand that these samples bridge the gap between our quality assurance and your confidence. This protects your brand. This guide will show you why holding onto these samples is so vital.

Ensuring Product Consistency Across Every Order

How do we make sure every piece of lingerie looks the same, every time? Using fixed examples helps a lot.

Ensuring product consistency across every intimate apparel order means using approved reference samples as the definitive benchmark. This helps you get the exact color, fabric feel, stitching, and fit for items like nursing bras or shapewear, maintaining your brand’s quality standards from the first batch to the last, no matter the volume.

As a buyer, you need to know that what you ordered last time will be the same as what you get next time. This is especially true for delicate items like lingerie. Imagine ordering a best-selling plus size bra set. If the color is slightly off or the lace pattern changes with each new order, your customers would notice. This inconsistency can damage your brand’s reputation. At XIESHENG, we use reference samples as our unwavering standard. Once you approve a sample for an item, say a sexy lingerie piece, that sample becomes the master guide for our production team. Our over 300 workers and QC team (more than 10 persons) refer to it for every single detail: the fabric type, the specific shade of dye, the stitching quality, and the precise measurements. This practice guarantees that every subsequent order, whether for ten thousand or a hundred thousand units, matches your original expectation perfectly. This gives you peace of mind and builds trust in our manufacturing capabilities.

Preventing Disputes Through Transparent Quality Comparison

How do we stop arguments about product quality? We use clear examples to compare and be fair.

Preventing disputes means using reference samples for transparent quality comparison. When you receive an intimate wear shipment, you can easily compare it against the approved sample, clearly seeing if the items, such as daily fashion bra sets or tennager intimate underwear, meet the agreed-upon standards, which helps avoid disagreements and fosters clear communication.

Disputes over product quality can be frustrating and costly for you, the buyer. They can delay sales and create tension between you and your manufacturer. My second tip highlights how reference samples prevent these issues. When a shipment arrives at your warehouse, you can simply pull out the approved reference sample and compare it directly with the delivered products. Is the elastic on the period panties as firm? Is the fabric on the bodydoll as soft? Does the cut of the nursing bra match? This direct comparison provides clear, undeniable evidence of whether the product meets the agreed-upon standard. This transparency eliminates guesswork and makes any quality discussions much more objective. At XIESHENG, we understand this. It is why we retain carefully labeled reference samples for key customers like WALMART and KIK. This practice helps us stand by our quality. It also gives you a clear tool for verifying your orders and ensuring satisfaction.

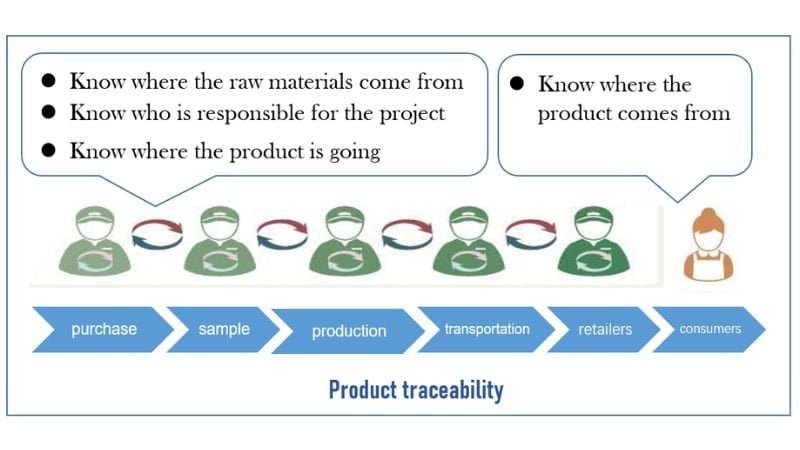

Supporting Buyer Traceability and Supply Chain Consistency

How do we track where lingerie came from and keep the whole process steady? Samples help us follow the path.

Supporting buyer traceability means using reference samples to link specific intimate apparel orders back to their production details and approved specifications. This allows you, the buyer, to maintain consistency within your ongoing supply chain, verify manufacturing benchmarks, and ensure every batch of products, like plus size bra sets, adheres to your evolving brand requirements.

For you, as a buyer managing a complex supply chain, traceability is vital. You need to know that your products are consistently made to specific standards, especially if you are working with multiple factories or sourcing a diverse range of items like sexy lingerie and shapewear. Reference samples play a crucial role here. Each sample is linked to a specific order, date, and sometimes even the raw materials used. This means that if you need to trace back a particular batch of daily fashion bra sets years later, the reference sample provides a clear physical record of what was approved. At XIESHENG, our quality control team uses these samples for internal audits. This ensures consistent production across our 10,000 sqm facility and our 20 sub-factories. This practice helps us maintain a consistent output that supports your brand’s reputation and compliance needs. It also helps manage historical data for you.

Standardizing Reorders and Repeat Production

How do we make reordering lingerie super easy and make sure it’s always perfect? Reference examples are the key.

Standardizing reorders and repeat production for your intimate apparel means you can confidently place new orders using the exact specifications from a stored reference sample. This simplifies the process for you and your manufacturer, eliminating the need to re-approve designs and accelerating the production cycle for popular items like tennager intimate underwear or fashion bra sets.

As a buyer, you know that some intimate apparel products become bestsellers for your brand or store. When this happens, you need to reorder them quickly and reliably. My fourth tip is about how reference samples make this process effortless. With a clearly approved reference sample on file, placing a reorder becomes much simpler. You do not need to resubmit detailed specifications or go through another lengthy approval process. You can simply reference the sample number or previous order details. This speeds up the entire supply chain. At XIESHENG, we keep an organized archive of reference samples for our long-term customers like DAISY FUENTES and ASHLEY. This system allows us to retrieve the exact specifications instantly. This ensures that every reorder of a popular period panty or nursing bra is produced identically. This standardization saves you time, reduces potential errors, and ensures a consistent flow of popular products to your customers.

Building Trust and Strengthening Long-Term Partnerships

How do we make sure our factory partners truly believe in us and keep working together for a long time? Trust and good work build strong ties.

Building trust and strengthening long-term partnerships in lingerie manufacturing hinges on transparent quality control processes, where reference samples are central. When you, as a buyer, consistently receive intimate apparel that matches the approved prototypes, it reinforces confidence in the manufacturer’s ability to deliver, fostering a reliable and lasting business relationship for your brand.

Ultimately, successful B2B procurement is built on trust and strong relationships. For you, as a buyer, it’s about finding manufacturers you can rely on for consistent quality and ethical practices over many years. My final tip emphasizes that using reference samples goes a long way in building this trust. When a manufacturer, like XIESHENG, consistently delivers intimate apparel that matches the approved reference samples, it builds immense confidence. You know that our production process is robust and our quality control is effective. This reliability is vital for creating long-term partnerships. It is why our factory has grown to include over 300 workers and manages relationships with major clients. By demonstrating our commitment to maintaining exact standards, we show you that we value your brand and your business. This, in turn, strengthens our partnership and ensures a secure supply chain for your intimate wear needs far into the future.

Conclusion

Reference samples are essential in lingerie manufacturing for buyers, ensuring product consistency, preventing quality disputes, supporting traceability, standardizing reorders, and building strong, trustworthy partnerships for enduring excellence.